Discover the world of high-quality display solutions with Kristel Displays, a leading name in the industry renowned for its High Brightness LCD Panels and Custom products, and legacy products. We specialize in custom LCD manufacturing and cater to a wide range of OEM markets. We deliver tailor-made solutions that meet specific environmental, mechanical, and electrical criteria.

Our capabilities span Optical Engineering, Electrical Engineering, Process Engineering, Mechanical Engineering, and Optical Bonding. Have questions? Our comprehensive FAQs section has you covered. Ready to transform your display needs? Give us a call at (630)-443-1290, and let’s start crafting your custom solution today.

In display technology, the evolution has been nothing short of revolutionary. From the rudimentary cathode ray tube (CRT) monitors to the sleek and vibrant TFT LCD screens we see today, the journey has been marked by constant innovation and improvement. This article delves into the world of TFT LCD technologies, shedding light on their significance in the current high-resolution era and how businesses across various sectors can benefit from these advancements.

TFT Display, or Thin Film Transistor technology, has emerged as a game-changer in the display industry. Its ability to control individual pixels on the screen results in superior image quality, making it a preferred choice for high-resolution applications. Kristel Displays, a world-class supplier of customized display solutions, has been at the forefront of leveraging TFT Display technology to deliver high-quality, cost-effective solutions to multiple OEM markets.

The role of TFT Displays in high-resolution technology cannot be overstated. It has paved the way for sharper, brighter, and more vibrant displays, enhancing the user experience manifold. With state-of-the-art TFT LCDs, Kristel Displays has been instrumental in pushing the boundaries of what’s possible in display technology, catering to industries ranging from Medical to Military and Food & Beverage.

Liquid Crystal Display or LCD technology has been a significant player in the display market. Known for its energy efficiency and versatility, LCD technology has applications in various devices, from digital watches to large television screens.

The role of LCD manufacturers in the tech industry is pivotal. They are the ones who bring this versatile technology to various devices we use daily. Kristel Displays, one of the leading LCD manufacturers, has consistently delivered high-quality LCD products catering to a wide range of applications, including kiosks, Industrial Control, Agricultural, Aviation, Gaming, and Transportation sectors.

In the diverse world of display technology, one size does not fit all. This is where the need for custom LCD solutions comes into play. Custom displays allow for more flexibility and adaptability, catering to the specific needs of different applications.

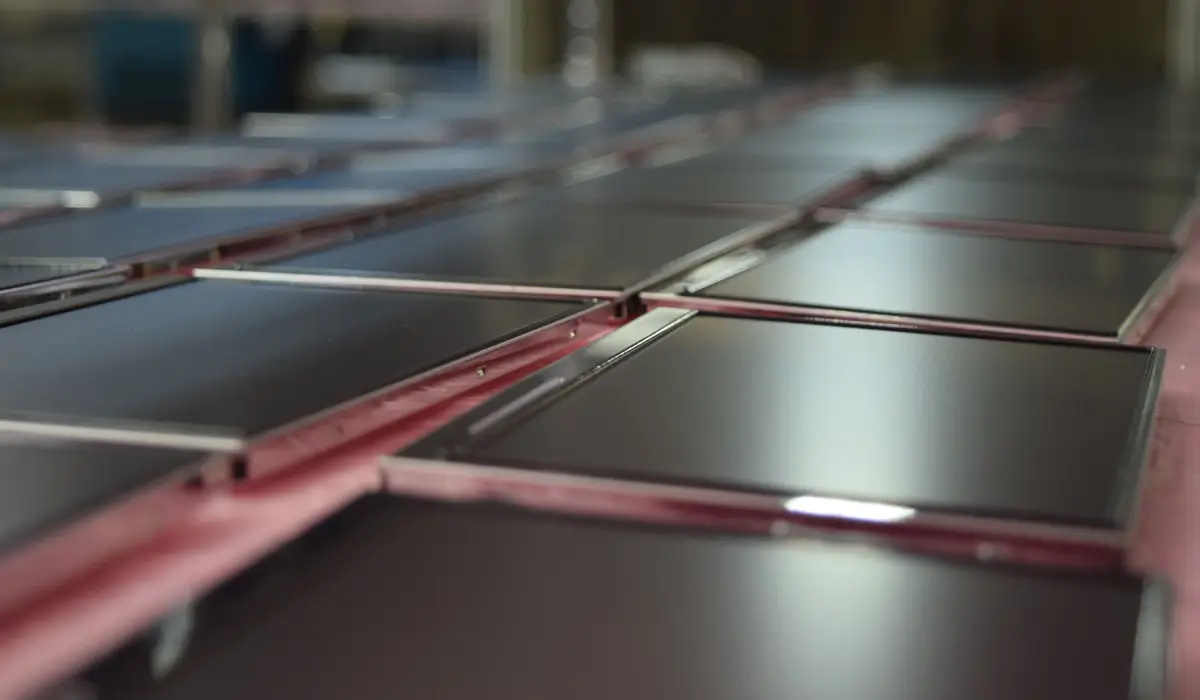

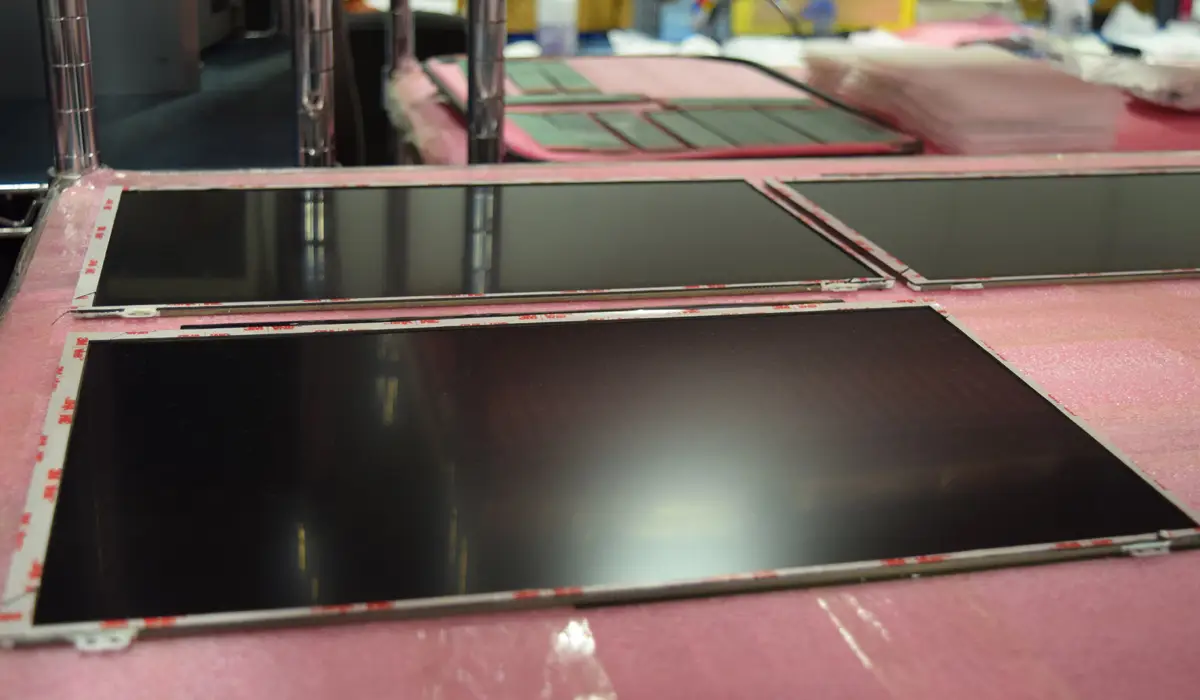

Kristel Displays stands out in its ability to provide custom LCD solutions. With a keen understanding of customer requirements and a robust manufacturing process, Kristel Displays has delivered tailor-made LCD solutions that hit the mark every time.

One of the critical processes involved in their manufacturing is the optical bonding service. With over 28 years of experience in the field, Kristel Displays’ proprietary process has produced hundreds of thousands of bonded displays with proven reliability.

Optical bonding involves a transparent adhesive layer between visual elements, such as a display panel and a cover glass. This creates a single optical unit with improved optical performance and increased durability. The adhesive helps protect the display from scratches and other damage. There are two main types of optical bonding: UV curing and thermal curing.

UV curing involves applying a UV-curable adhesive to the two optical elements and then curing it using ultraviolet light. In thermal curing, a bond that cures at high temperatures is applied to the two visual elements and then fixed using heat. This process manufactures various displays, including LCD, LED, and OLED.

The benefits of optical bonding include improved visual performance due to eliminating the air gap between the two optical elements, increased durability, and reduced manufacturing costs by simplifying the assembly process. These capabilities allow Kristel Displays to design a customized open-frame display or a complex All-In-One (AIO) display system.

In conclusion, the importance of TFT LCD technology in today’s high-resolution era cannot be overstated. These technologies have revolutionized how we interact with digital devices, unprecedentedly enhancing the user experience. As we move forward, companies like Kristel Displays will continue to lead the way, pushing the boundaries of what’s possible in display technology and offering businesses across various sectors the opportunity to leverage these advancements for their success.

Experience the difference between superior display technology with Kristel Displays. From High Brightness LCD Panels to Custom products and legacy products.

We offer a diverse portfolio designed to meet your unique needs. Our expertise in custom LCD manufacturing and comprehensive capabilities in Optical Engineering, Electrical Engineering, Process Engineering, Mechanical Engineering, and Optical Bonding set us apart in the industry. For any queries, our FAQs section is just a click away. Ready to elevate your display experience? Don’t hesitate to contact us at (630)-443-1290, and let’s bring your vision to life.

A TFT or Thin Film Transistor is a type of LCD that uses thin film transistor technology to improve image quality. Each pixel on a TFT is attached to a transistor and capacitor, allowing for faster response times and better control over color and brightness.

TFT technology allows for individual control of each pixel on the screen, resulting in superior image quality. This makes it a preferred choice for high-resolution applications, as it can deliver sharper, brighter, and more vibrant displays.

TFT offer several advantages over other types of displays. They provide better image quality, faster response times, and higher resolution. Additionally, they have wider viewing angles and can display more colors, enhancing the overall user experience.

TFT are more energy efficient than older display technologies like CRT. However, they may consume more power than other types of LCDs due to the additional transistors. The exact energy efficiency can vary based on the specific model and usage.

TFT are used in a wide range of applications due to their high-quality image display. They are commonly found in televisions, computer monitors, smartphones, tablets, and other devices that require high-resolution displays.

Both TFT and OLED offer high-quality displays, but they work differently. While TFT technology controls individual pixels through transistors, OLED uses organic compounds that emit light when an electric current is applied. OLED can offer deeper blacks and a higher contrast ratio. Still, TFTs are typically more cost-effective and have a longer lifespan.

The lifespan of a TFT can vary based on usage and care, but on average, they can last for several years. It’s important to note that over time, the brightness of a TFT may decrease due to the natural degradation of the backlight.

Yes, certain types of TFT are designed for outdoor use. These displays typically have high-brightness backlights and anti-reflective coatings to ensure visibility even in bright sunlight.

Absolutely. Due to their fast response times and high-resolution capabilities, TFT are an excellent choice for gaming. They can deliver smooth, vibrant images that enhance the gaming experience.

The future of TFT technology looks promising. With ongoing advancements, we can expect even higher resolutions, faster response times, and more energy-efficient designs. Developing flexible TFT could also open up new possibilities in wearable technology and beyond.